8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

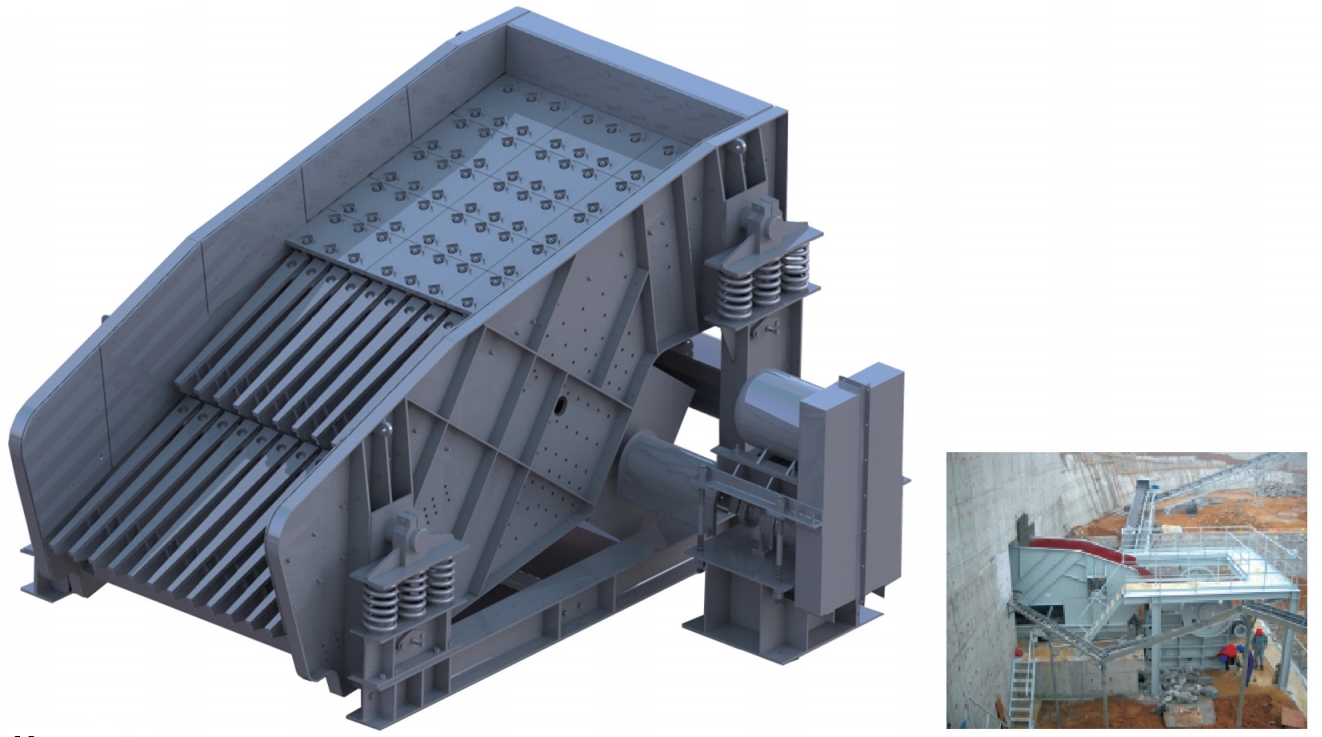

GZT vibrating feeder screening machine is a kind of vibrating feeder screening equipment. This equipment is mainly used in mining, metallurgy, coal, and other industries to feed the crusher after pre-screening. Generally, it is installed under the material bin, and it can carry the load and start. The equipment has reasonable structure, large bearing capacity, strong impact resistance, stable and reliable operation, and convenient installation and maintenance.

product details

Industry solutions:● The vibrator is an eccentric block vibrator, which is directly installed on the double I-beam. It has a solid structure and can enhance the rigidity of the screen frame. The screen bearings are evenly arranged, with large exciting force and strong load-bearing capacity. The eccentric block of the vibrator is forcibly synchronized through the gear, the movement is smooth and reliable, and the material runs at a uniform speed.

● The bearing lubrication adopts rare lubrication, the oil film is fully lubricated, the service life is relatively long, and maintenance is convenient. The sealing method adopts skeleton oil seal and rubber gasket seal.

● The plates are rolled from Ansteel. The shape cutting and positioning holes of the steel plate are completed by high-precision CNC cutting machines to ensure the accuracy of the shape and drilling position. Reinforcing ribs or protective plates are reasonably arranged in the areas where the side plates are subject to greater stress to effectively increase the strength of the side plates.

● The upper part of the screen frame is an I-beam, and the lower part is a double I-beam, which makes the overall rigidity of the screen frame stronger, impact-resistant, and has a large material holding capacity. It can be started with material load to meet the needs of large particle size and large processing capacity.

● The position of the vibrator is scientifically arranged and fixed at the back and lower part of the screen box. The position here has high stiffness and the material comes from top to bottom. The vibrator vibrates from bottom to front, which is very reasonable.

● The drive device uses a motor to reduce speed through a V-belt and a pulley, and then through the driver, using a universal drive shaft to directly connect to the vibrator. The V-belt protects the motor, and then decelerates through the pulley to select the optimal speed. Through the direct connection between the driver and the universal shaft, when starting and stopping, due to the nature of the cardan shaft, it will not be affected by excessive vibration during starting and stopping.

Technical Parameters

Feeder model | Layer No. | Screening surface size(mm) | Screen area(m²) | Opening size(mm) | Power(Kw) |

GZT0725 | 1 | 700×1540 | 1.1 | 80~300 | 11 |

GZT0926 | 1 | 900×1530 | 1.3 | 80~300 | 11 |

GZT1245 | 1 | 1210×2430 | 2.9 | 80~300 | 22 |

GZT1260 | 1 | 1260×2920 | 3.4 | 80~300 | 37 |

GZT1545 | 1 | 1560×2000 | 3 | 80~300 | 37 |

GZT1548 | 1 | 1560×2820 | 4.2 | 80~300 | 45 |

GZT1560 | 1 | 1560×3310 | 4.9 | 80~300 | 45 |

GZT1848 | 1 | 1860×2580 | 4.5 | 80~300 | 55 |

GZT1860 | 1 | 1860×3310 | 5.9 | 80~300 | 55 |

GZT2448 | 1 | 2460×2580 | 6 | 80~300 | 55 |

GZT2460 | 1 | 2460×3310 | 7.9 | 80~300 | 75 |

GZT3048 | 1 | 3060×2570 | 7.5 | 80~300 | 75 |

GZT3060 | 1 | 3060×2870 | 8.4 | 80~300 | 90 |

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap