8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

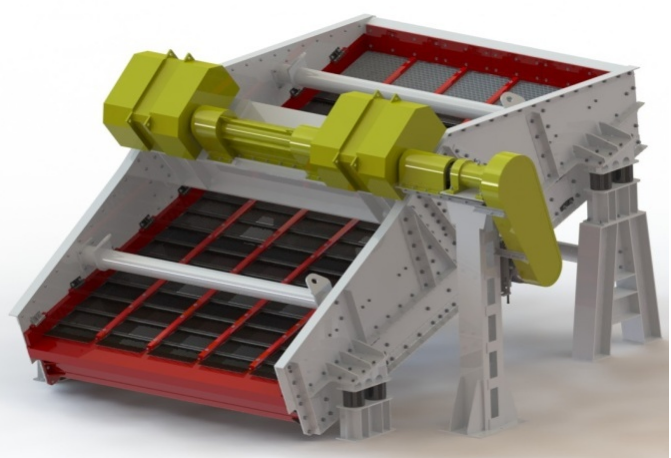

Efficient self-cleaning sizing screen is mainly used for classification of raw coal particle size in the coal industry, especially suitable for dry deep classification of granular coal (6mm ~ 13mm) and screening of coal used in power plants, and for raw coal with special viscosity and moisture (including external moisture 7-14) and bad conditions, the screening efficiency can reach more than 70%.

product details

Industry solutions:lThe whole screen has compact structure, small covering area, large vibrating parameters:n=970r/min、2A=10~12mm、 K=5.23g~6.31g,Angle of vibrating direction is 65°, make it work efficiently.

lThe screen panel adopts elastic cantilever bar plate, the material is wear-resisting and elastic manganese steel, the screen bar vibrates with the main machine at the same time, can generates secondary vibration independently, effectively solves the problems of critical particles、materials with special viscosity and moisture blocking the hole, makes its screening efficiency up to more than 90%.

lOpening area rate of screen panel is high, handling capacity of unit area is large. Compared with the conventional screen which has the same opening area rate, handling capacity is increased by 1.5 times; Screen panel has long service life (more than 6 months), the price is cheaper than the screen panel of flip-flop screen, the maintenance cost is low.

lAll parts and components of the screen frame are assembled with cold riveting technology to avoid all internal stresses of the assembly. The cross beam adopts rectangular square beam structure with strong rigidity and stable、reliable operation.

Technical Parameters

Screen model | Layer No. | Screening surface size(mm) | Screen area(m²) | Opening size(mm) | Power(Kw) |

GZFS1848g | 1 | 1840X4880 | 8.98 | 6-25 | 22 |

GZFS2448g | 1 | 2450X4880 | 11.96 | 6-25 | 30 |

GZFS3048g | 1 | 3050X4880 | 14.88 | 6-25 | 37 |

GZFS3055g | 1 | 3050X5490 | 16.74 | 6-25 | 37 |

GZFS3648g | 1 | 3670X4880 | 17.91 | 6-25 | 45 |

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap