8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

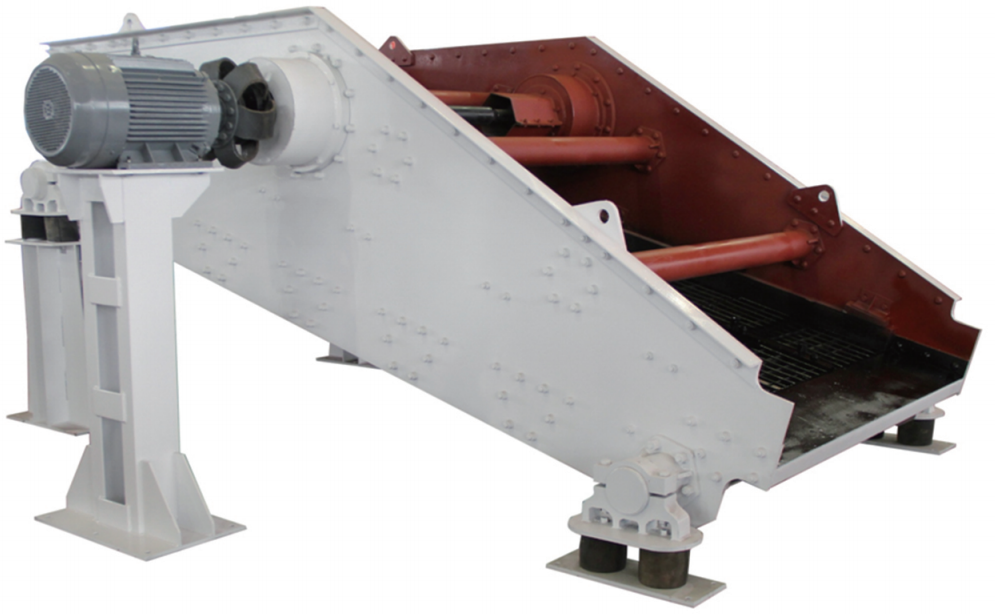

YK series circular vibrating screens are mainly used in coal, metallurgy, mining, electric power, water conservancy, building materials, light industry and chemical industries, to classify medium and fine-grained materials. This product can reach the international leading level, and has the characteristics of long bearing life, good vibration reduction effect, low noise, durability and high screening efficiency.

At the same time, according to different working conditions and user needs, an automatic dry oil lubrication system and an online detection system can be configured to monitor data such as revolutions, amplitude, and bearing temperature in real time.

product details

Industry solutions:lIt adopts block eccentric exciter, the bearing seal is lubricated with grease, and the special labyrinth design is simple and reliable.

lThe side panels are finished by high-precision CNC cutting machine tools, which ensures the accuracy of the shape and drilling. The side panels and beams use high-strength HUCK ring groove rivets and cold riveting technology, with advanced structures and no welding stress.

lThe cross beam adopts a round tube beam structure design, and the surface can be equipped with an optional adhesive plate.

lThe screen panel can be woven screen or plate screen panel.

lThe spring adopts rubber spring, so the car starts and stops quickly through the resonance zone.

lThe drive system uses two motors connected with the vibrator through a flexible coupling, which is simple and reliable.

Technical Parameters

Screen model | Layer No. | Screening surface size(mm) | Screen area(m²) | Opening size(mm) | Power(Kw) |

YKg1230 | 1 | 1250X3000 | 3.6 | 3-50 | 7.5 |

YKg1536 | 1 | 1550X3600 | 5.4 | 3-50 | 11 |

YKg1645 | 1 | 1650X4500 | 7.2 | 3-50 | 18.5 |

YKg1836 | 1 | 1850X3600 | 6.48 | 3-50 | 15 |

YKg1845 | 1 | 1850X4500 | 8.1 | 3-50 | 15 |

YKg1848 | 1 | 1850X4800 | 8.64 | 3-50 | 15 |

YKg2045 | 1 | 2050X4500 | 9 | 3-50 | 18.5 |

YKg2048 | 1 | 2050X4800 | 9.6 | 3-50 | 18.5 |

YKg2052 | 1 | 2050X5250 | 10.5 | 3-50 | 18.5 |

YKg2060 | 1 | 2050X6000 | 12 | 3-50 | 22 |

YKg2430 | 1 | 2450X3000 | 7.2 | 3-50 | 15 |

YKg2448 | 1 | 2450X4800 | 11.5 | 3-50 | 30 |

YKg2452 | 1 | 2450X5250 | 12.6 | 3-50 | 30 |

YKg2460 | 1 | 2450X6000 | 10.2 | 3-50 | 30 |

YKg3060 | 1 | 3050X6000 | 18 | 3-50 | 30 |

YKg3060 | 1 | 3050X6000 | 18 | 3-50 | 30 |

2YKg2060 | 2 | 2050X6000 | 12X2 | 3-100 | 30 |

2YKg2452 | 2 | 2450X5250 | 12.48X2 | 3-100 | 30 |

2YKg3060 | 2 | 3050X6000 | 18X2 | 3-100 | 30 |

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap