8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

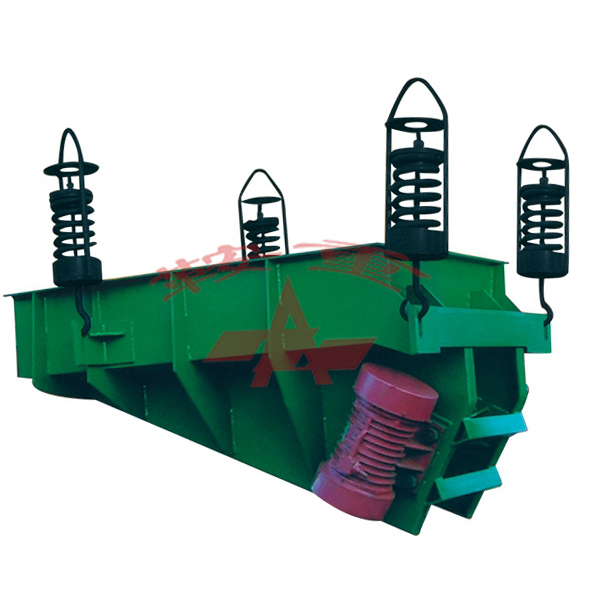

A vibrating feeder is a kind of commonly used feeding equipment. It can uniformly and continuously send block or granular materials to the receiving equipment during production. It is the first process of the entire production line. Later, it is often crushed with a jaw crusher. The working efficiency of the vibrating feeder not only has an important impact on the production capacity of the jaw crusher but also has an impact on the production efficiency of the entire production line.

Some users reported that the vibrating feeder had slow feeding problems, which affected production. Today vibrating feeder exporter will share 4 reasons and solutions for the slow feeding of vibrating feeders.

1. The slope of the chute is not enough

Solution: Adjust the installation angle. Choose the fixed position of the height/lower feeder according to the site conditions.

2. The included angles of the eccentric blocks at both ends of the vibration motor are inconsistent

Solution: Adjust after checking whether the two vibration motors are consistent.

3. The vibration direction of the vibration motor is the same

Solution: It is necessary to adjust the wiring of any one of the vibration motors to ensure that the two motors operate in reverse to ensure that the vibration track of the vibration feeder is linear.

4. Insufficient excitation force of vibration motor

Solution: It can be adjusted by adjusting the position of the eccentric block (the excitation force is adjusted by adjusting the phase of the eccentric block. One of the two eccentric blocks is fixed and the other is movable. Just loosen the bolts of the movable eccentric block. When the phases of the eccentric blocks coincide, the excitation force is the largest, and it decreases in order; when adjusting, ensure that the phases of the eccentric blocks of the same group of motors are consistent).

(1) Check and eliminate any debris that affects the movement of the body such as materials between the body and the chute, springs, and supports;

(2) Check whether all fasteners are fully tightened;

(3) Check whether the lubricating oil in the exciter is higher than the oil mark height;

(4) Check whether the transmission belt is in good condition, replace it in time if it is damaged, and clean it if there is oil stain;

(5) Check whether the protective device is in good condition, and remove any unsafe phenomena in time.

(1) Check whether the machine and transmission parts are normal before starting;

(2) Must start under no load;

(3) After starting, if an abnormal situation is found, the machine should be shut down immediately, and the machine can be restarted only after the abnormality is found and eliminated.

(4) The machine can run with materials only after stable vibration;

(5) Feeding should meet the requirements of a load test run;

(6) The shutdown should be carried out according to the process sequence, and it is forbidden to stop with materials or continue feeding during or after the shutdown.

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap