8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

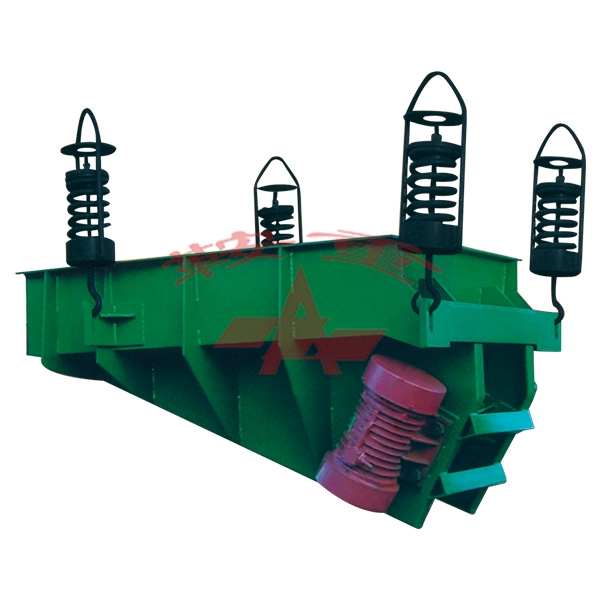

Vibrating feeder uses the centrifugal force generated by the rotation of the eccentric block in the vibrator to make the movable parts such as screen compartment and vibrator move in a forced continuous circular or near-circular motion. This equipment is widely used in crushing and screening joint equipment in metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasives and other industries.

Vibrating feeder is composed of feeding trough, exciter, spring support, transmission device and so on. The vibration source of the trough vibrating feeder is the exciter, the exciter is composed of two eccentric shafts (main and passive) and gear vice, driven by the motor through the v-belt active shaft, and then the gear on the active shaft engages the passive shaft rotation, the main and passive shafts reverse rotation at the same time, so that the trough body vibration, so that the continuous flow of materials to achieve the purpose of conveying materials.

The feeding process of vibrating feeder is realized by using the special vibrating motor to drive the feeding trough to make periodic linear reciprocating vibration along the inclination direction. When the vertical component of acceleration of feeding trough vibration is greater than the acceleration of gravity, the materials in the trough will be thrown up and jump forward according to the parabolic trajectory, and the throwing and dropping will be completed within 1/50 seconds.

1.vibrating feeder for batching, quantitative feeding to ensure uniform and stable feeding, to prevent material self-flow should be installed horizontally, such as continuous feeding of general materials, can be installed at 10 ° downward tilt. For viscous materials and materials with large water content can be installed at 15 ° downward tilt.

2.After installation, the feeder should be left with a 20mm travel gap lateral should be horizontal, the suspension device using a flexible connection.

3.Before the test run, all the bolts should be tightened once, especially the ground bolts of the vibration motor, 3-5 hours of continuous operation should be tightened once again.

4.The test run of the two vibration motors must be reversed rotation, current and noise stability, abnormalities found should be stopped in time to deal with.

5.Motor bearings every 2 months to fill a grease, high temperature season should be filled once a month with lubricant.

1.the feeder in the process of operation should always check the amplitude, vibration motor current and motor surface temperature, the requirements before and after the amplitude of uniform, not swinging around, vibration motor current stability, if abnormalities are found, should be immediately stopped to deal with.

2.vibration motor bearing lubrication is the key to the normal operation of the whole feeder, in the process of use should be regularly refilled bearings difluxed molybdenum 2 # grease, once every two months, once a month during the high temperature season, once every six months to disassemble the motor, replace the internal bearings.

Correct operation and proper maintenance can make the vibrating feeder service life longer and more ideal efficacy.

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap