8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

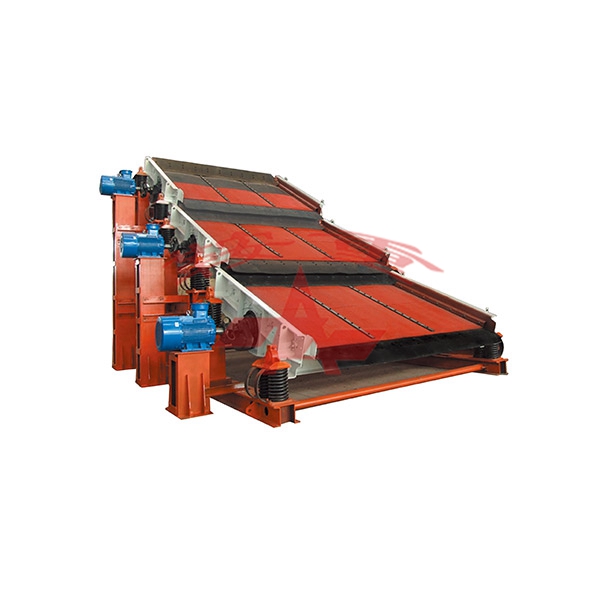

A vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening.

The screens serve to classify the different particles by size, starting from a bulk product in a continuous process. The inlet material (the raw product) advances from the part where the screen is fed to the opposite end in which the particles come out separately according to their size, shape or density. There are also vibrating screens that are loaded by the centre and the product moves radially to the outputs that are on the periphery.

For the correct advancement of the product, it is necessary that the process is continuous, and it is due to the vibration if the screening surface is horizontal. Most of the screens have a certain inclination in such a way that the advanced movement of the product is due to a combination between gravity and vibration.

Vibrating screens are equipment used to separate and transport granulated materials in various processes throughout the mining, agriculture, pharmaceutical, food, and chemical industries.

Different types of vibrating screens can be used for the same material to get different screening effects. The reasonable selection of a vibrating screen is an effective way to improve vibration efficiency and maximize economic benefits. Generally, you need to consider the following 5 tips:

When choosing a vibratory screen, the material characteristics should be taken into account, including the content of material particles under the screen, the content of difficult screen particles, material moisture, the shape and specific gravity of the material, and the content of clay.

Tips: Heavy vibrating screen is used for materials above 200mm; a circular vibrating screen is used for materials above 10mm; a linear vibrating screen and high frequency vibrating screen are used for desliming, dewatering and grading.

Vibratory screens need to be selected according to different screening purposes. If it is necessary to pre-screen materials, circular vibrating screens are generally used; for the classification and screening of crushed materials, large vibrating screens and probability screens are selected; for the deionization and dehydration of materials, linear vibrating screens are better; if it is necessary to eliminate and clean up materials, probability screens are used.

When selecting the vibratory screen, the screen areas, layer numbers, shape, size and area ratio of the screen holes, as well as the motion mode, vibration frequency and amplitude of the vibrating screen should also be considered.

The screening efficiency of the vibratory screen is related to the motion form of the screens, so the fixed screen is lower than that of the moving screen.

Tips: In order to keep the screens under good working conditions, the ratio of screen length to width should be in the range of 2-3; when there are much viscous mud and high moisture in the material, double deck screens should be avoided as far as possible.

When selecting the shale shakers, it also needs to be considered according to the processing capacity of the production line, screening method, screening efficiency and the tilt angle of the shale shakers.

Professional vibrating screen manufacturers could provide competitive vibrating screen price, diverse customized vibrating screen models, timely after-sales service, spare parts and can continue to provide services for customers’ whole production circle.

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap