8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

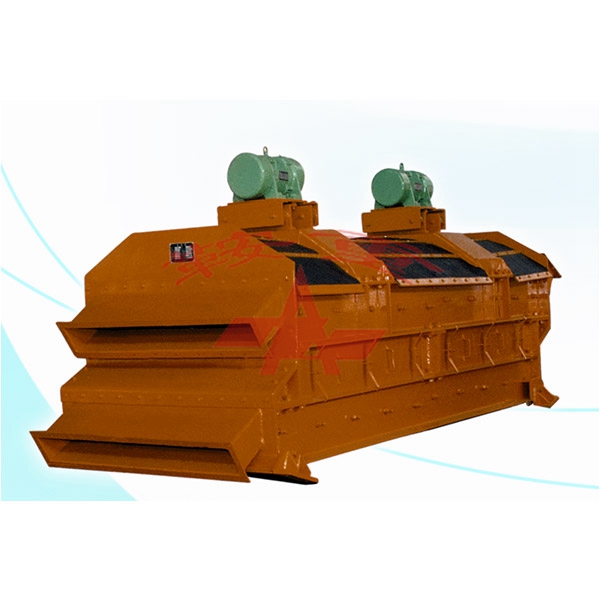

The process of breaking bulk materials into different particle levels through one or several layers of screen surface is called sieving. The sifter is a vibrating sieving machine that uses the relative movement of the bulk material and the sieve surface to make some of the particles pass through the sieve holes, dividing the sand, gravel, crushed stone and other materials into different levels according to the size of the particles.

The sieving machine screening process is generally continuous, screening raw materials to the screening machinery (referred to as sieve) after, less than the size of the sieve hole material through the screen hole, known as the sieved product; greater than the size of the sieve hole material from the screen surface continuously discharged, known as the product on the screen.

Screening machinery is necessary auxiliary equipment in the mining crushing and sand production line, and its selection has an important impact on the final product's particle size. The vibrating screen supplier will share the selection of screening machinery skills.

The main factors that should be considered when selecting the type of sifter are.

1. The characteristics of the screening material (the content of the particle size under the screen, the content of difficult to screen particles, the content of moisture and clay in the material, the shape of the material, the specific gravity of the material, etc.).

2. The structure of the screening machine (screen area, number of screen layers, screen hole size and shape, screen hole area rate, screen movement, amplitude and frequency, etc.)

3. The requirements of the beneficiation process (processing capacity, screening efficiency, screening method, screen inclination), etc.

(1) 200mm or more materials, more heavy vibrating screen; 10mm or more materials, more circular motion sieve; desliming, dewatering and classification more linear vibrating screen, high frequency vibrating mesh screen.

(2) For the sieve to be in good working conditions, the ratio of sieve length to width should be selected within the range of 2 to 3.

(3) A reasonable sieve surface material and structure should be selected to suit the working conditions.

(4) sieve hole size determination, for fine sieve, arc sieve, linear vibrating screen for fine-grain sieving its sieve slit size for the separation of particle size 2 to 2.2 times, the maximum does not exceed 3 times; for vibrating sieve, for medium size material sieving, its sieve hole size for the separation of particle size 1.2 times; for coarse-grain material sieving, sieve hole size for the separation of particle size 1.05 can; for probability sieve, sieve hole size generally For the actual separation size of 2 to 2.5 times.

(5) Determine whether to use a double or multi-layer sieve. In the sieved material grain range is wide, the use of double-layer sieve as a single-layer sieve, can improve the processing capacity of the sieve machine, but also protect the lower layer of the screen so that the lower layer of the screen use period is extended. Double layer sieve of the upper screen sieve hole size selection, generally should be based on the characteristics of the size of the ore to determine, can be considered according to the upper screen under the amount, equivalent to 55-65% of the original feed material size as a sieve hole size.

Note that when the content of the under-screen particle size in the raw material exceeds 50%, there are more difficult to screen particles, more viscous mud and high moisture in the material, the use of a double-deck sieve as a single-deck sieve should be avoided as far as possible.

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap