8 Major Advantages of Anzhong

8 Major Advantages of Anzhong+86 152 4210 2697

Crushers, grinders, and pulverizers are grinding equipment used to convert or reduce coarse materials (such as stone, coal, or slag) into smaller and finer materials. Grinding equipment can be divided into two basic types: crushers and grinders. Industrial crushers are the first level of particle size reduction; further granulation occurs in the grinder or pulverizer.

The crusher reduces the material through the crusher and the crusher, and the crusher or the moving parts of the crusher will crush the material when the material is under pressure. The force applied during this process may be compression, shear, or impact. When the internal strain level reaches a critical level, the material ruptures. When a material breaks, it releases energy mainly as heat.

Several scientific theories for size reduction have been developed, including Ridinger's law, Kick's law, and Bond's law.

Crusher

Industrial crushers crush or deform materials through impact or pressure, thereby reducing large pieces of rock, ore, or waste to a smaller size. During the primary crushing operation, the boulder size feed is reduced from 20 to 100 inches to the secondary crusher size of 1 to 20 inches or the ground feed size of 0.5 to 3 inches.

There are many different types of crushers with different designs and crushing processes. The correct choice depends on several factors, including the hardness of the material to be crushed, the grinding performance of the material, the moisture content, and the required reduction rate. The following table lists various crusher types and their general specifications and uses.

Type | Hardness | Abrasion limit | Moisture content | Reduction ratio | Main use |

Horizontal shaft impactors | Soft to medium-hard | Slightly abrasive | Dry or wet, not sticky | 10/1 to 25/1 | Quarried materials, sand & gravel, recycling |

Vertical shaft impactors (shoe and anvil) | Medium hard to very hard | Slightly abrasive | Dry or wet, not sticky | 6/1 to 8/1 | Sand & gravel, recycling |

Vertical shaft impactors (autogenous) | Soft to very hard | No limit | Dry or wet, not sticky | 2/1 to 5/1 | Quarried materials, sand & gravel |

Cone crushers | Medium hard to very hard | Abrasive | Dry or wet, not sticky | 3/1 to 5/1 | Quarried materials, sand & gravel |

Jaw crushers

| Soft to very hard | No limit | Dry to slightly wet, not sticky | 3/1 to 5/1 | Heavy mining, quarried materials, sand & gravel, recycling |

Gyratory crushers | Soft to very hard | Abrasive | Dry to slightly wet, not sticky | 4/1 to 7/1 | Heavy mining, quarried materials |

Compound crusher | Medium hard to very hard | Abrasive | Dry or wet, not sticky | 3/1 to 5/1 | Mine, building materials |

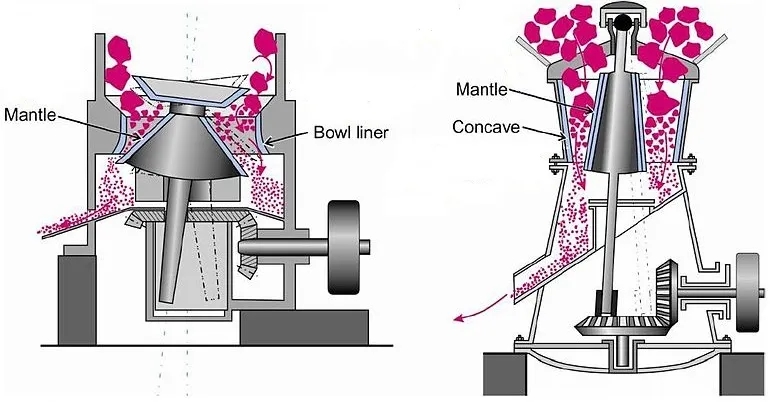

The cone crusher uses a rotating cone that rotates in the bowl in an eccentric manner to break the rock between the cone surface (called the sleeve) and the lining of the bowl of the crusher. The rotary crusher is very similar to the cone crusher, but the cone has a steeper slope and the bowl surface is concave. When the gap between the bowl lining and the mantle narrows, the rock is crushed between the mantle by the revolving cone.

The horizontal axis of the horizontal shaft impactors (HSI) rotates a heavy-duty rotor. The guide bar attached to the rotor throws the material to be crushed towards the anti-collision apron (or curtain) equipped with replaceable bushings. Using the principle of surface force, this impact will damage the material and reduce the production of the material.

Adjust to 1/10 to 1/25 of the original size.

Cone Crusher (left) and Gyratory Crusher (right)

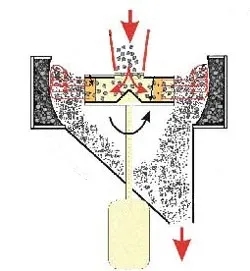

The vertical shaft impactor (VSI) has a vertical axis and a closed rotor, which can rotate at high speed. There are two main types of VSI crushers, namely rock crushing (self-generating) crushers, and shoe anvils. The pit of the rock crusher is filled with the entire circumference of the rock-filled chamber. Shoe-type and anvil-type VSI crushers have composite metal alloy anvils, and their placement positions can maximize the impact of materials thrown to the fixed anvil by centrifugal force. The comparison with the cone crusher shows that the VSI crusher has higher energy efficiency and can produce more fine materials under the same working conditions and time range.

VSI Crusher

The jaw crusher uses mechanical pressure to force the material to move between two vertical jaws. The two jaws are fixed and the other is driven back and forth. As the material moves through the crusher, the gap between the two jaws narrows, thereby further reducing the size. Jaw crushers are heavy machinery that can be used for hard materials in mining or quarries.

Anshan Anzhong Mining Machinery Co., Ltd.

swan0119

No.294 Anqian road, Gaoxin district, Anshan, Liaoning,China

Copyright © Anshan Heavy Duty Mining Machinery Co., Ltd. All Rights Reserved | Sitemap